คำอธิบายผลิตภัณฑ์:

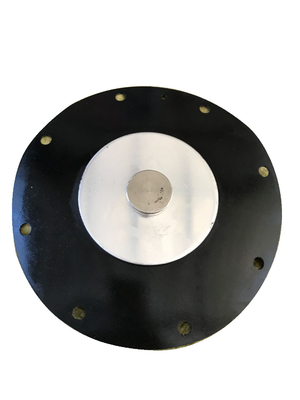

ไดอะแฟรมโซลินอยด์วาล์วเป็นส่วนประกอบสำคัญที่ออกแบบมาเพื่อเพิ่มประสิทธิภาพและความน่าเชื่อถือของระบบโซลินอยด์วาล์วต่างๆ โดยเฉพาะอย่างยิ่งในการใช้งานที่ต้องการการควบคุมการไหลของของเหลวหรือก๊าซอย่างแม่นยำ ผลิตจาก NBR (Nitrile Butadiene Rubber) คุณภาพสูง ไดอะแฟรมนี้มีความทนทานต่อการสึกหรอ น้ำมัน และความร้อนได้ดีเยี่ยม ทำให้มั่นใจได้ถึงความทนทานยาวนานแม้ภายใต้สภาวะการทำงานที่ต้องการประสิทธิภาพสูง ความเข้ากันได้กับช่วงแรงดัน 0 ถึง 10 บาร์ ทำให้เหมาะสำหรับสภาพแวดล้อมที่มีแรงดันต่ำและปานกลาง ทำให้สามารถใช้งานได้หลากหลายในหลายอุตสาหกรรม

ไดอะแฟรมนี้ได้รับการออกแบบมาโดยเฉพาะสำหรับการใช้งานในวาล์วโซลินอยด์นิวเมติกแบบ 2 ทาง ซึ่งใช้กันอย่างแพร่หลายในระบบอัตโนมัติเพื่อควบคุมการไหลของอากาศหรือก๊าซอย่างมีประสิทธิภาพ การกำหนดค่าแบบ 2 ทางช่วยให้การทำงานแบบเปิด/ปิดทำได้ง่าย ทำให้เหมาะสำหรับการใช้งานที่ต้องการการทำงานของวาล์วแบบเปิด/ปิดที่เชื่อถือได้ ด้วยความสามารถในการซีลที่แม่นยำ ไดอะแฟรมช่วยให้มั่นใจได้ถึงการรั่วไหลน้อยที่สุด จึงรักษาความสมบูรณ์และประสิทธิภาพของระบบนิวเมติก การออกแบบที่แข็งแกร่งยังช่วยลดความถี่ในการบำรุงรักษา จึงช่วยเพิ่มประสิทธิภาพการทำงานโดยรวม

หนึ่งในคุณสมบัติเด่นของไดอะแฟรมโซลินอยด์วาล์วนี้คือการผสานรวมกับกลไกชนิดคอยล์โซลินอยด์ การทำงานด้วยคอยล์ช่วยให้วาล์วตอบสนองได้อย่างรวดเร็วและแม่นยำ ซึ่งมีความสำคัญอย่างยิ่งสำหรับระบบที่เวลาและการควบคุมมีความสำคัญ เมื่อกระแสไฟฟ้าไหลผ่านคอยล์โซลินอยด์ จะสร้างสนามแม่เหล็กที่เปิดใช้งานไดอะแฟรม ทำให้ของเหลวสามารถผ่านหรือปิดได้ การควบคุมด้วยไฟฟ้าแบบนี้ทำให้ไดอะแฟรมตอบสนองได้ดีและเหมาะสำหรับการตั้งค่าอัตโนมัติที่ต้องการการทำงานของวาล์วระยะไกลหรือตั้งโปรแกรมได้

หลักการทำงานเบื้องหลังไดอะแฟรมนี้คือการทำงานโดยนักบิน ซึ่งหมายความว่าจะใช้ความแตกต่างของแรงดันทั่วทั้งวาล์วเพื่อช่วยในการทำงาน การทำงานโดยนักบินนี้ช่วยลดการใช้พลังงานของคอยล์โซลินอยด์ได้อย่างมาก เนื่องจากไดอะแฟรมต้องการแรงดันนำร่องเพียงเล็กน้อยในการกระตุ้นวาล์วหลัก คุณลักษณะนี้มีประโยชน์อย่างยิ่งในการใช้งาน เช่น เครื่องชงกาแฟ ซึ่งวาล์วโซลินอยด์เครื่องชงกาแฟต้องทำงานอย่างมีประสิทธิภาพและเชื่อถือได้โดยไม่ใช้พลังงานมากเกินไป การออกแบบที่ทำงานโดยนักบินยังช่วยเพิ่มความสามารถของวาล์วในการรับแรงดันที่สูงขึ้น ทำให้เหมาะอย่างยิ่งสำหรับข้อกำหนดของวาล์วโซลินอยด์แรงดันสูง

การติดตั้งทำได้ง่ายด้วยการออกแบบแบบขันสกรู ทำให้สามารถติดตั้งเข้ากับตัววาล์วหรือระบบที่มีอยู่ได้อย่างปลอดภัยและง่ายดาย การติดตั้งประเภทนี้ช่วยให้มั่นใจได้ถึงความพอดีที่แน่นหนา ป้องกันการรั่วไหล และรักษาความสมบูรณ์ของแรงดันของระบบ คุณสมบัติแบบขันสกรูยังช่วยให้เปลี่ยนหรือบำรุงรักษาได้อย่างรวดเร็ว ลดเวลาหยุดทำงานและค่าใช้จ่ายในการบริการ ไม่ว่าจะอยู่ในระบบอัตโนมัติทางอุตสาหกรรม การจ่ายเครื่องดื่ม หรือระบบนิวเมติกอื่นๆ การติดตั้งแบบขันสกรูช่วยให้โซลูชันที่ใช้งานได้จริงและเป็นมิตรกับผู้ใช้สำหรับช่างเทคนิคและวิศวกร

โดยสรุป ไดอะแฟรมโซลินอยด์วาล์วเป็นส่วนประกอบประสิทธิภาพสูงที่ปรับแต่งมาเพื่อใช้ในวาล์วโซลินอยด์นิวเมติกแบบ 2 ทาง รวมถึงการใช้งานพิเศษ เช่น วาล์วโซลินอยด์เครื่องชงกาแฟ การสร้างจากวัสดุ NBR ที่ทนทาน ความสามารถในการทำงานภายในช่วงแรงดัน 0 ถึง 10 บาร์ และหลักการทำงานโดยนักบิน ทำให้เป็นตัวเลือกที่เหมาะสำหรับระบบที่ต้องการการทำงานของวาล์วโซลินอยด์ที่เชื่อถือได้ มีประสิทธิภาพ และแรงดันสูง การเปิดใช้งานคอยล์โซลินอยด์ร่วมกับการติดตั้งแบบขันสกรูช่วยเพิ่มการใช้งานจริงและความสะดวกในการใช้งาน ทำให้มั่นใจได้ว่าจะตอบสนองความต้องการที่สูงของระบบนิวเมติกและการควบคุมของเหลวสมัยใหม่

คุณสมบัติ:

-

ชื่อผลิตภัณฑ์: ไดอะแฟรมโซลินอยด์วาล์ว

-

พอดีกับ: วาล์วนิวเมติกโซลินอยด์วาล์ว ASCO

-

วัสดุ: NBR คุณภาพสูง (Nitrile Butadiene Rubber)

-

ช่วงแรงดัน: 0 ถึง 10 บาร์

-

แรงดันใช้งาน: 0-10 บาร์ เพื่อประสิทธิภาพที่เชื่อถือได้

-

ความหนา: 1.5 มม. เพื่อความทนทานและความยืดหยุ่น

-

เหมาะสำหรับการใช้งานวาล์วโซลินอยด์นิวเมติกแบบ 2 ทาง

-

เหมาะสำหรับการใช้งานวาล์วโซลินอยด์เครื่องชงกาแฟ

-

เหมาะสำหรับระบบวาล์วโซลินอยด์ช่วงล่างอากาศ

พารามิเตอร์ทางเทคนิค:

|

ช่วงอุณหภูมิ

|

-20°C ถึง 80°C

|

|

ขนาดช่อง

|

3/4 นิ้ว

|

|

วัสดุ

|

NBR (Nitrile Butadiene Rubber)

|

|

ประเภทคอยล์

|

โซลินอยด์

|

|

แรงดันไฟฟ้าในการทำงาน

|

12V / 24V / 110V / 220V (ขึ้นอยู่กับโซลินอยด์วาล์ว)

|

|

หลักการทำงาน

|

ทำงานโดยนักบิน

|

|

แรงดัน

|

0-10 บาร์

|

|

พอดี

|

วาล์วนิวเมติกโซลินอยด์วาล์ว ASCO

|

|

การซีล

|

การซีลที่ดี

|

|

ความหนา

|

1.5 มม.

|

การใช้งาน:

ไดอะแฟรมโซลินอยด์วาล์ว HONGUM เป็นส่วนประกอบสำคัญที่ออกแบบมาสำหรับการใช้งานและสถานการณ์ที่หลากหลายซึ่งจำเป็นต้องมีการควบคุมของเหลวที่เชื่อถือได้ ออกแบบด้วยยางไนไตรล์บิวทาไดอีนคุณภาพสูง (NBR) ไดอะแฟรมนี้มีความทนทานและทนทานต่อสารเคมีได้ดีเยี่ยม ทำให้เหมาะสำหรับการใช้งานในระบบไฮดรอลิกและนิวเมติกที่ทำงานภายในช่วงแรงดัน 0-10 บาร์ ความทนทานต่ออุณหภูมิตั้งแต่ -20°C ถึง 80°C ช่วยให้มั่นใจได้ถึงประสิทธิภาพที่สม่ำเสมอในสภาพแวดล้อมที่หลากหลาย ไม่ว่าจะอยู่ในเครื่องจักรอุตสาหกรรมหรือการใช้งานยานยนต์

หนึ่งในสถานการณ์การใช้งานหลักสำหรับไดอะแฟรมโซลินอยด์วาล์ว HONGUM คือในระบบที่ใช้คอยล์โซลินอยด์วาล์วไฮดรอลิก ในการตั้งค่าดังกล่าว ไดอะแฟรมทำหน้าที่เป็นซีลที่ยืดหยุ่นซึ่งควบคุมการไหลของของเหลวและแรงดัน ป้องกันการรั่วไหลและรับประกันการทำงานของวาล์วที่เหมาะสมที่สุด ประเภทการติดตั้งแบบขันสกรูช่วยลดความซับซ้อนในการบำรุงรักษาและการเปลี่ยน ทำให้สามารถติดตั้งได้อย่างรวดเร็วและปลอดภัยในวงจรไฮดรอลิก สิ่งนี้ทำให้เหมาะสำหรับการใช้งานในเครื่องอัดไฮดรอลิก ระบบกำลังของเหลว และอุปกรณ์อื่นๆ ที่ต้องการการควบคุมของเหลวที่แม่นยำ

อีกหนึ่งแอปพลิเคชันที่โดดเด่นคือในวาล์วโซลินอยด์ช่วงล่างอากาศ ซึ่งไดอะแฟรมมีบทบาทสำคัญในการจัดการแรงดันอากาศเพื่อรักษาประสิทธิภาพของช่วงล่างของรถยนต์ วัสดุยางไนไตรล์ทนทานต่อการสึกหรอและรักษาความยืดหยุ่นภายใต้สภาวะอุณหภูมิที่แตกต่างกัน ซึ่งมีความสำคัญอย่างยิ่งสำหรับระบบช่วงล่างอากาศของรถยนต์ที่สัมผัสกับสภาพอากาศและสภาพถนนที่ผันผวน ไดอะแฟรม HONGUM ช่วยให้มั่นใจได้ถึงการควบคุมการไหลของอากาศที่ราบรื่นและเชื่อถือได้ ซึ่งมีส่วนช่วยให้ผู้โดยสารรู้สึกสบายและเสถียรภาพของรถยนต์

นอกจากนี้ ไดอะแฟรมโซลินอยด์วาล์ว HONGUM ยังใช้กันอย่างแพร่หลายในวาล์วควบคุมไฮดรอลิกต่างๆ ที่ติดตั้งคอยล์โซลินอยด์วาล์วไฮดรอลิก โครงสร้างที่แข็งแกร่งและความเข้ากันได้กับการติดตั้งแบบขันสกรูมาตรฐานทำให้เป็นตัวเลือกที่ยอดเยี่ยมสำหรับระบบอัตโนมัติทางอุตสาหกรรม เครื่องจักรกลการเกษตร และระบบบำบัดน้ำ ความยืดหยุ่นของไดอะแฟรมต่อการต้านทานน้ำมัน เชื้อเพลิง และของเหลวไฮดรอลิกอื่นๆ ช่วยเพิ่มอายุการใช้งานของชุดวาล์ว ลดเวลาหยุดทำงานและค่าใช้จ่ายในการบำรุงรักษา

โดยสรุป ไดอะแฟรมโซลินอยด์วาล์ว HONGUM เหมาะอย่างยิ่งสำหรับระบบไฮดรอลิกและนิวเมติกที่ต้องการโซลูชันการซีลที่เชื่อถือได้ภายใต้แรงดันสูงสุด 10 บาร์ และอุณหภูมิระหว่าง -20°C ถึง 80°C การใช้งานครอบคลุมคอยล์โซลินอยด์วาล์วไฮดรอลิก วาล์วโซลินอยด์ช่วงล่างอากาศ และอุปกรณ์ควบคุมของเหลวอื่นๆ ทำให้เป็นส่วนประกอบที่ขาดไม่ได้สำหรับอุตสาหกรรมที่เน้นประสิทธิภาพ ความทนทาน และประสิทธิภาพ

การสนับสนุนและบริการ:

ผลิตภัณฑ์ไดอะแฟรมโซลินอยด์วาล์วของเราได้รับการออกแบบมาเพื่อประสิทธิภาพที่เชื่อถือได้และมีประสิทธิภาพในการใช้งานทางอุตสาหกรรมที่หลากหลาย เพื่อให้มั่นใจถึงการทำงานที่ดีที่สุด สิ่งสำคัญคือต้องปฏิบัติตามแนวทางการติดตั้งและการบำรุงรักษาที่แนะนำ

มีการสนับสนุนด้านเทคนิคเพื่อช่วยเหลือในการเลือกผลิตภัณฑ์ การแก้ไขปัญหา และคำแนะนำในการใช้งาน ทีมผู้เชี่ยวชาญของเราสามารถช่วยวินิจฉัยปัญหาที่เกี่ยวข้องกับประสิทธิภาพของวาล์ว เช่น การรั่วไหล การไม่ทำงาน หรือการทำงานที่ไม่สอดคล้องกัน

เราขอแนะนำให้ตรวจสอบและทำความสะอาดไดอะแฟรมเป็นประจำเพื่อป้องกันการปนเปื้อนและการสึกหรอ ควรติดตั้งไดอะแฟรมทดแทนตามข้อกำหนดของผู้ผลิตเพื่อรักษาความสมบูรณ์และฟังก์ชันการทำงานของวาล์ว

สำหรับการบริการและการซ่อมแซม ให้ใช้เฉพาะชิ้นส่วนอะไหล่ของแท้เพื่อให้แน่ใจว่าเข้ากันได้และปลอดภัย บริการสนับสนุนของเราประกอบด้วยคำแนะนำเกี่ยวกับขั้นตอนการซ่อมแซมและตารางการบำรุงรักษาเชิงป้องกันเพื่อยืดอายุการใช้งานของไดอะแฟรมโซลินอยด์วาล์วของคุณ

เรามุ่งมั่นที่จะให้การสนับสนุนและบริการด้านเทคนิคที่ครอบคลุมเพื่อเพิ่มประสิทธิภาพและอายุการใช้งานของผลิตภัณฑ์ไดอะแฟรมโซลินอยด์วาล์วของคุณ

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!  ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!